Reliable labware

Built to retain Quality

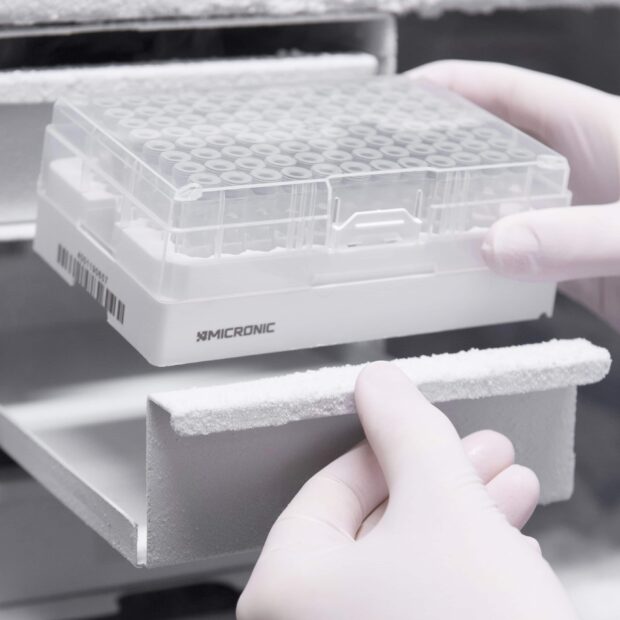

It is common for research laboratories to thaw samples in order to retrieve a small amount of material for research. After thawing, the remaining sample is frozen again. This freeze-thaw process can happen many times in any given period of time. For this reason, it is important that sample integrity is maintained; avoiding weight loss, major tube cracks, and caps coming off the tubes.

Micronic regularly conducts research on the stability of their tubes and caps with regard to freeze-thaw cycles. A frequent analysis of the freeze-thaw stability on Micronic tubes and caps provides a safe and reliable recognition of Micronic products among customers. In order to get valid results, instead of only doing a freeze test, a freeze-thaw test has been conducted.